French

STS Hoist Ropes for Container Terminals | Reduced Downtime

Ship-to-Shore (STS) Hoist Ropes for Container Terminals

Ship-to-shore container crane operations are unforgiving. With downtime costs measured in tens of thousands of dollars per hour, rope selection directly impacts crane availability, maintenance workload, and terminal profitability.

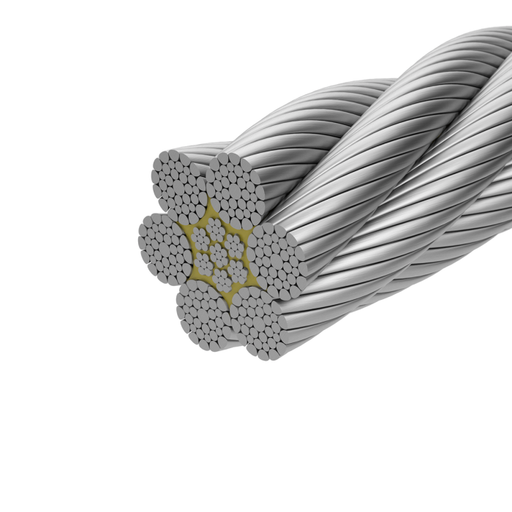

Across global ports, 6×36 IWRC hoist ropes are commonly selected due to their lower initial cost per foot and their tolerance for incidental external damage. In deep vessel operations, where hoist ropes are routinely exposed to container contact, crushing, and impact, this accidental damage can account for 30% or more of total rope change-outs, independent of normal fatigue wear.

While this approach appears economical on the surface, the hidden operational penalties of uncompacted 6-strand ropes are rarely quantified.

The Hidden Cost of 6×36 Hoist Ropes in STS Cranes

Uncompacted 6-strand constructions exhibit higher elastic and constructional elongation, which introduces several systemic inefficiencies in modern STS cranes:

-

Increased load variation and differential stretch between paired hoist ropes

-

Accelerated wear of trolley tensioner and compensation systems

-

Frequent maintenance interventions to remove slack and re-equalize reeving

-

Reduced moves per hour, as control systems compensate for changing rope tension

-

Higher sheave groove wear, commonly observed at rates up to 30% greater than with compacted, high-stability rope designs

As slack develops within the reeving system, ports often experience higher rope kill rates, inconsistent hoist behavior, and reduced predictability in maintenance planning—ultimately offsetting any perceived savings in initial rope cost.

Why Leading Ports Are Switching to Teufelberger STS Hoist Ropes

Teufelberger’s advanced hoist rope designs—engineered specifically for the largest crane manufacturers in the world—address these issues at the system level:

-

Higher axial stiffness and reduced elongation

-

Superior load sharing between paired hoist ropes

-

Improved diameter stability and lower surface pressure, reducing sheave and drum wear

-

Lower tensioner activity and reduced hydraulic stress

-

Significantly longer service intervals

Ports that have transitioned to Teufelberger hoist ropes consistently report:

-

50% to 200% more moves between change-outs

- Increase in moves per hour

-

Lower accidental and premature rope discard rates

-

Improved crane availability and maintenance predictability

-

Meaningful reductions in total cost of ownership (TCO)

More Than a Rope — A System Upgrade

Choosing Teufelberger is not simply a component change. It is a measurable improvement to crane performance, maintenance efficiency, and operational uptime.

Today, 160+ container ports worldwide rely on Teufelberger hoist ropes to reduce downtime, improve safety, and stabilize long-term operating costs.

Speak With a Port Crane Rope Specialist

If you are evaluating STS hoist rope performance, kill rates, or maintenance costs at your terminal, we can help.

📧 Email: dean@vrsltd.ca

📍 Serving ports across North America and Globally

-

REDAELLI PACK 1P

Original price $0.00 - Original price $0.00Original price$0.00$0.00 - $0.00Current price $0.00| /PACK 1P: Compacted 6-Strand Wire Rope with Plastified Steel Core The PACK 1P wire rope, distributed by Vancouver Rigging Supply Ltd., combines stre...

View full details -

TEUFELBERGER EVOLUTION QS816V

Original price $0.00 - Original price $0.00Original price$0.00$0.00 - $0.00Current price $0.00| /The EVOLUTION QS816V steel wire rope, part number QS816V, offers exceptional resistance to external factors in building construction and civil engi...

View full details